Two Wheelers Part

We at United engineer’s Limited can provide the complete range of motorcycle products. We have wide range of models suitable for Honda, Yamaha, Suzuki, AKT, Yumbo, Bajaj, TVS, and Hero MotoCorp.Transmission Chain

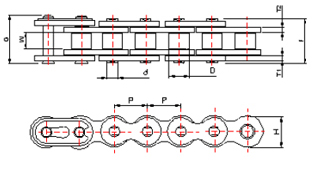

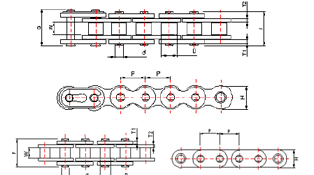

Transmission Chain is designed and manufactured to exacting standards employing leading edge technology, material selection, tooling, heat treatment and manufacturing methods.

Heat treatment: In NDE chain, pins and bushes are provided with optimum surface hardness through skilled use of heat treatment for long durability.

Shot peened parts: All plates and rollers are shot peened to improve fatigue life. Shot peening induces compressive forces in these parts and therefore offers high resistance against fatigue and impact loading.

Preloading of the chain: NDE chain is preloaded in special fixtures. This enhances resistance against initial elongation and fatigue. All chains are subject to precise length control.

Greater fatigue and tensile strength: the wider waist of NDE link plates, combined with optimum press fitted bushes and pins, ensures greater fatigue strength.

Piston Rings

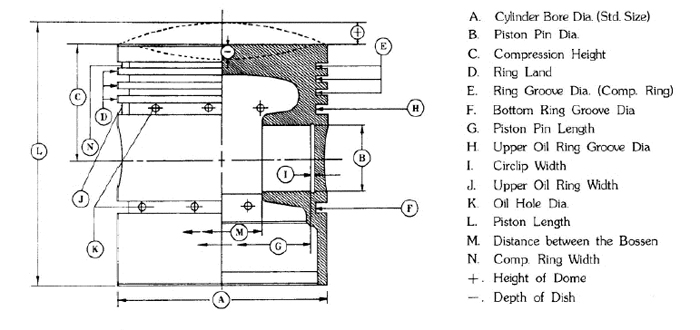

Piston Kits

Best aluminum alloy is being used to produce piston to achieve the desired and targeted performance. Our highly qualified engineer’s quality control ensure the best quality to our customers.

Features

- Detonation free cycle.

- Maximum fuel efficiency, least sunburn fuel.

- No carbon deposit reduces the detonation.

- Maximum power transfer.

- Best heat transfer, reducing pre-ignition.

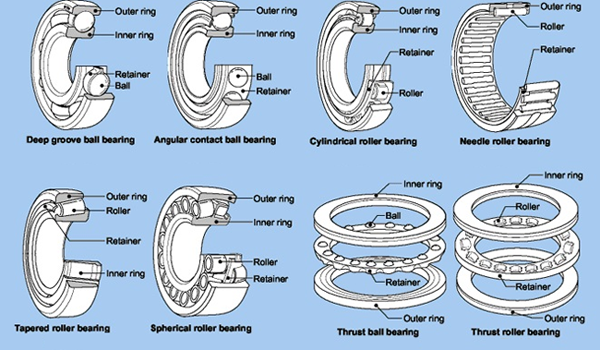

Bearings

- BEARINGS are manufactured to standard grades of precision with established tolerances for size and geometric accuracy. These standards are known as ABEC classes.

- MATERIAL used high class bearing steel as per the recommended grade and type of bearing. 52100 chrome steel for maximum fatigue life.

- Proper lubrication is essential for the successful performance of any bearing. NDE’s lubricants have been selected to best reduce friction, prevent wear, carry away heat and protect bearing surfaces from corrosion.

- Control condition heat treatment of the outer and inner race being done.

- High quality steel and plastic seals used to product the lubrication to the maximum.

Connecting Rods

- Best Material used as per Japanese’s JIS standard 20CrMo, molybdenum steel used for better shock resistance.

- To ensure the better life of connecting rods, forging is being at very closely controlled temperature, to keep the grain structure uniform inside the core.

- To improve wear ability and shock resistance at high speed of the engine, small and big end being induction hardened. Smooth and uniform hardening depth.

- Big and Small end sizes are being maintained under fine grinding, surface roughness maintained at 0.10 Ra and size control within 10 micron. Both these specifications provide smooth fitment with bearing and pin, which contribute minimum power loss.

- Bearings selected for optimum quality and performance.

Click here to download details

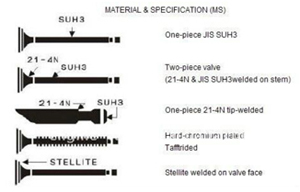

Engine Valve

- Best Material used as per Japanese’s JIS standard SUH-35 (5Cr21Mn9Ni4N) for both inlet and exhaust valve.

- Head angle closely ground to Ra 0.4 um roughness and 90°+1°, run out within 0.03 mm, which guarantee least possible pressure leakage at high temperature and speed .Head radius and exit angles have been controlled in forging to get easy flow of gases.

- Valve stem diameter closely ground to Ra 0.4 um roughness , size tolerance 0.02 mm , 0.005 mm cylindericity, nitrided to 0.008 mm min thickness hardness 600 HV min, This provide long life to stem. Stem tip is welded with superficial alloy Stellite to give hardness as 50-60 HRC

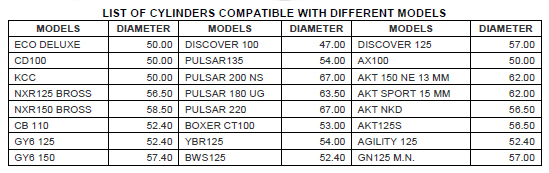

Motorcycle Cylinder Block

- UEL cylinders have been made using high strength ADC12 aluminum alloy.

- UEL cylinders are made by using state of the art pressure die- casting machines , where the material flow is uniform which helps the inside structure to stay micro cracks free.

- UEL cylinders have been checked 100% for any micro crack after pressure die casting.

- cylinders take iron wear resistant alloy with high quality as basal body of cylinder, uniformly dense microstructure that promotes durability and reliability. Its wear resistance is 60% higher than that of boron cast iron

- The cylinder bore is carefully machined and plateau-honed to produce a crosshatch pattern that retains oil. This promotes break-in of piston ring surfaces to minimize oil consumption and eliminate ring scuffing.

- cylinders and pistons come pre-assembled from the factory to ensure proper alignment of the piston rings.

- Piston kits are with graphite coating to provide the best wearing strength.

- Piston rings are of high quality, which uses alloy steel with nitriding (First Ring) and spheroidal cast iron (second ring), this results in minimum pressure leakage, hence improve the efficiency.

- Gasket is made of asbestos free graphite facing, solid steel core sealing gaskets.

- All parts are manufactured and tested by the latest OEM specifications in order to restore the original quality and performance of engine.

Motorcycle Sprockets

- Sprockets are being made with good quality steel as per the customer requirement.

- Tight tolerances on all dimensions to get the optimum fitment without any unwanted gap increase the perfect messing with chains to get best life.

- Controlled Heat treatment, better life.

- ISO tooth profile. Perfect meshing with chain

- Controlled Zinc passivation for longer life of antirust prevention.

Motorcycle Battery

UEL offer a complete range of conventional dry charged, maintenance free and sealed maintenance free lead acid batteries for all motorcycle, scooters, ATVs and lawn movers.

Our batteries are produced from high grade Lead antimony alloy. Plates charged and cured with digitally control system to give more consistency in plate quality. Automatic soldering of plates and terminals, make our battery flaw less in high vibration conditions.

UEL batteries are being tested 100% for leakage online. Our batteries are achieving the capacity test up to 115% as per JIS standard.

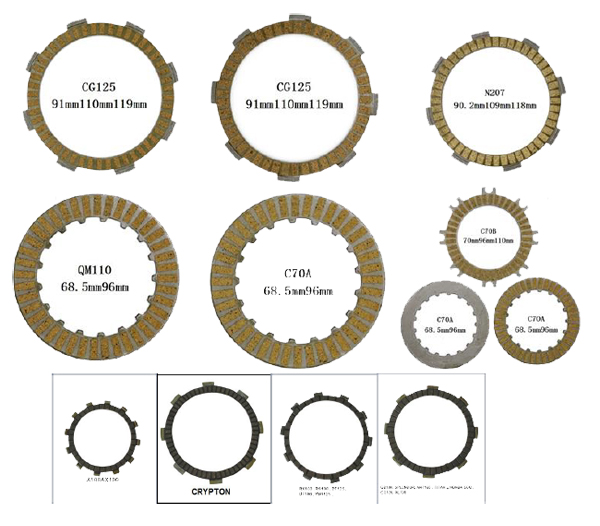

Motorcycle Clutch Plates

- Aluminium alloy individually casted to get maximum strength.

- Automatic line for glue application, to get maximum bonding of aluminium and friction material. Zero peel off.

- Proprietary friction material composition, Hi-torque capability at minimum wear.

- Close tolerance, no clutch noise, No drum wear.

- Ground to almost zero flatness, No slippage of clutch even under adverse clutch conditions.

Motorcycle Shock Absorber

- Nickel hard chrome plated fork pipe for smooth functioning.

- Specially blended front fork suspension oil for superior/consistent performance.

- High quality rubber material to prevent oil seal life.

- High quality spring used for good driving comfort.

- High Strength sintered parts used for smooth and long life.